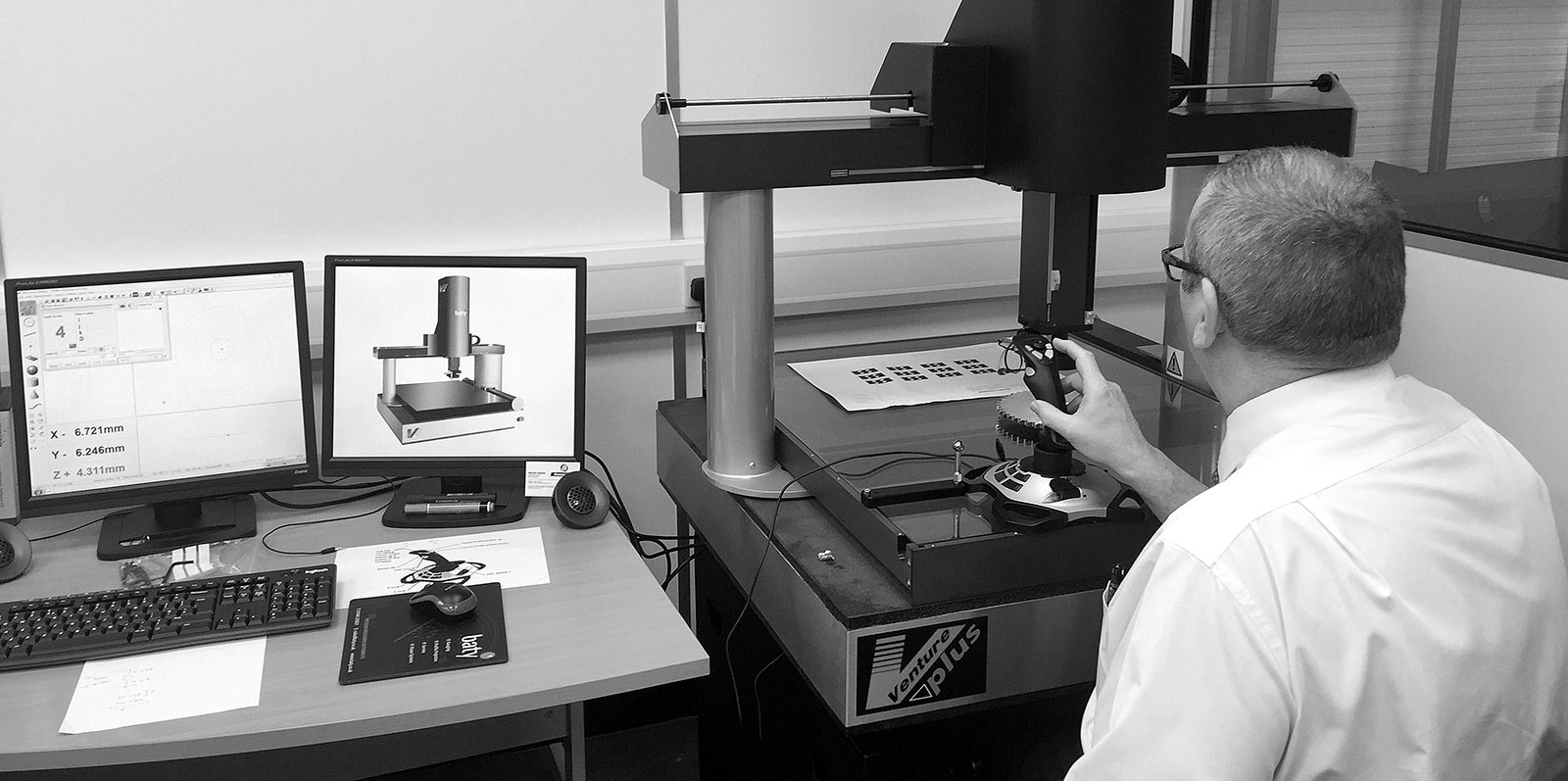

Our Laboratory includes a range of high precision technical equipment. A Component Measuring Machine (CMM) which uses a fine optical probe, combines both a powerful microscope and camera functionality to not only accurately measure any component, but also analyse material grain structure and identify faults. This high specification system, which self-calibrates to ensure it’s always set up correctly, measures to 2 microns – a human hair is 100 microns!

As well as conformance, we can test for concentricity, bore size and parallelism of high precision parts. For example, by inserting the tolerances of a sprocket from the approved drawing into the computer programme, the system automatically measures the bore size (centre of a sprocket) switching to camera to locate and measure each outer tooth, constantly checking and comparing the data against the original drawing. Bespoke sprockets made to close tolerances are being tested in our laboratory.

Our Innovatest 600 machine can test the hardness of chain components and identify whether they are case hardened or not. This is useful when testing both new and used materials, reporting against Rockwell Hardness Scale C, and identifying why a product may have failed or has the potential to do so. The accuracy of this machine conforms to EN ISO 6508 and ASTM E-18.

With companies facing significant fines for chain failure in use, for example on fork lift trucks, and in order to satisfy stringent H&S legislation and avoid costly reworking, it is vital to ensure that your product is accurately tested and guaranteed fit for purpose.

We can undertake Inspection Reports for any make of chain or sprocket and report on failure or non-conformance; multiple product testing, subject to size, may be undertaken with a typical two day turnaround.

We’d love to hear from you.

Whether you have a question about our products, services or prices, our UK team is ready to answer all your questions.